(603)-742-8812

Established In 1981

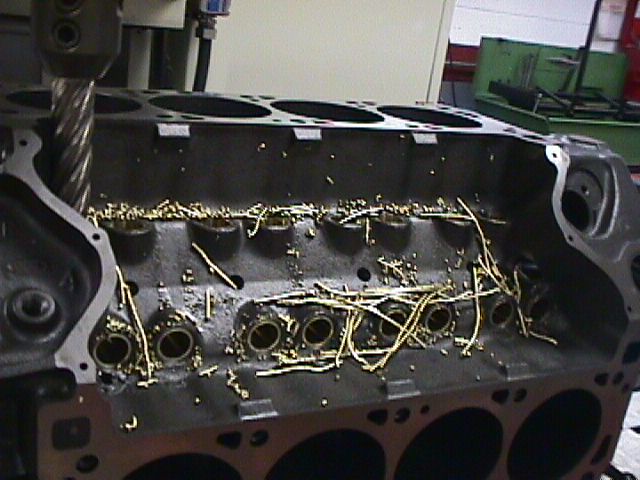

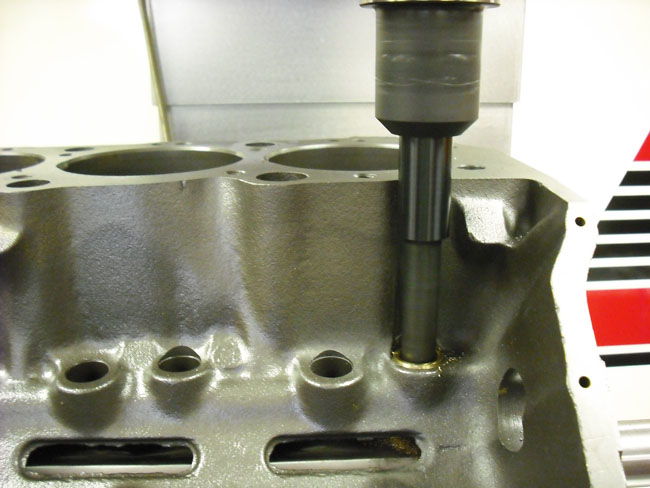

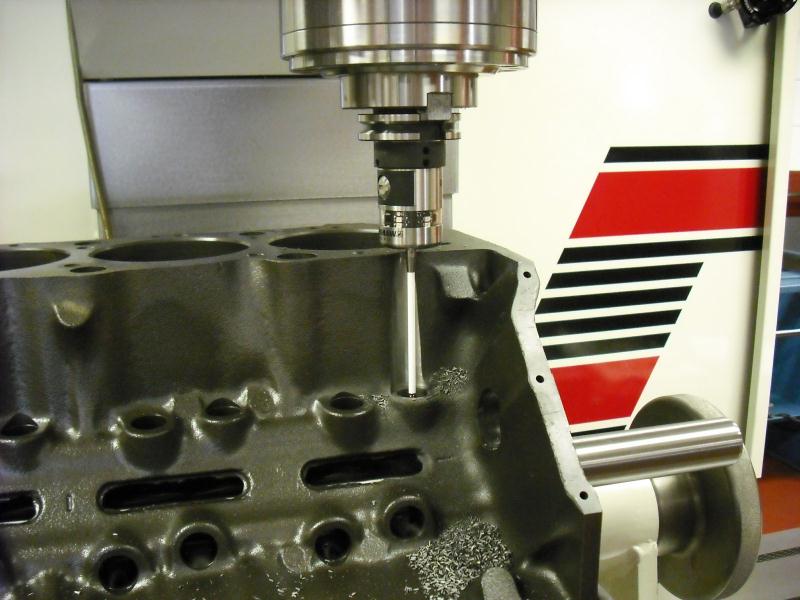

Lifter Bore Sleeve Installation Lifter Bore Correction CNC Probed and Located

Lifter Bushing Ford 351 C

The Rottler Lifter-True blueprinting fixture allows R & L Engines to re-machine the lifter bores and correct their position in an engine block front-to-rear and up-and-down, as well as to restore the correct lifter bore angle as referenced from the cam-crank centerline. In addition, we utilizes the Rottler F69A CNC Engine Block Blueprinting machine with the lifter blueprinting program to positions the precise blueprinted lifter bore location. The CNC Probing System is extremely accurate. Boring tools will not drift like an end mill allowing precise lifter bore blue printing.

Step 1 probe, Step 2 spot face , Step 3 end Mill, Step 4 Bore on Blue print Location Step 5 Install Bushing (Not Shown)

Step 6 Finish Bore for Lifter Fit

Rottler CNC Engine Block Blueprinting Machine utilizes the Lifter Bore Blueprinting program and CNC probing to locate the lifter bore right on blueprint specifications The Lifter Bores are machined to exacting tolerances from engine manufacturers blueprint specifications bore center to center are maintained. The Rottler performance blueprinting fixture insures the proper main and cam centerline references are corrected and maintained.The CNC routine includes probing the lifter bore locations , relocation to blue print specs and probing for verification of the corrected locations

Note: Click on pictures to enlarge and see slides. This works on most picture in our site.