(603)-742-8812

Established In 1981

Engine Rebuilding -Automotive Machine Shop

Vintage - Marine & Performance Engines

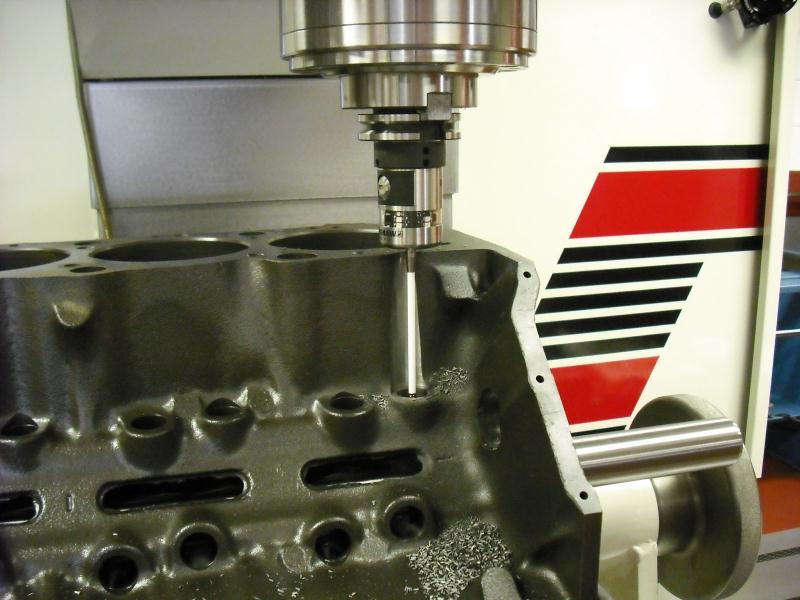

Boring for Darton Honda Sleeving.

Block blue printing starts with the crankshaft main line. This surface is corrected with the CNC line bore process. The block decks and cylinder bores are corrected to the crankshaft and camshaft centerline. The cylinder bores are then bored on center distances to blueprint specs. This process is achieved through the use of a datum fixture that references the crankshaft and camshaft centerline at a true 45 degrees. The block is probed from the centerline then indicated from the dowel location. This enables the bore spacing to be corrected and blue printing the deck surfaces square to the camshaft and crankshaft centerline at a true 45 degree angle is achieved..The dimensions are imputed to the CNC control holding tolerances to 0001. This accuracy is achievable with CNC machinery and specialized Datum plates, and tooling.

CNC Engine Block Blueprinting & Machining CNC Line Boring

CNC Lifter Correction- Roller Cam Bearing- Darton Sleeve

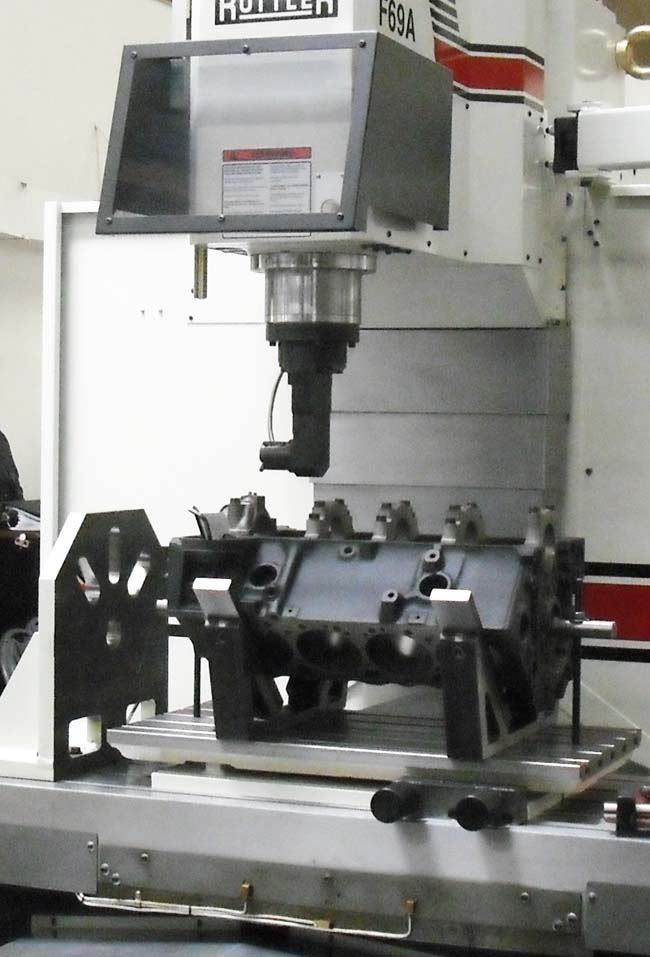

Rottler F69A CNC Engine Block Blueprinting & CNC Machining Center

State of the art machining capabilities operated by expert machinists. These machines are specifically designed for High Performance Engine Block Blue Print machining operations. Custom machine your components 1 part at a time. OEM'S use the Pan Rail as The machining Datum. This is why deck heights are not at a true 90 or equal height end to end.Cylinder bore locations and even lifter bore distances and locations are not on Blue Print Specification. R & L Engines has invested in Rottler F69A CNC Equipment with 4 th axis and probing processes to correct bore center spacing , deck heights and lifter bore locations. Our fixtures are based from the main line and cam shaft centerline. The process will increase Horse Power while Improving overall Engine Performance. Your Hot Rod, Vintage Restoration, Marine Engine, or Race Engine will perform at peak performance levels. R & L utilizes the best components and machining processes. R&L Engines will satisfy even the most demanding requirements.

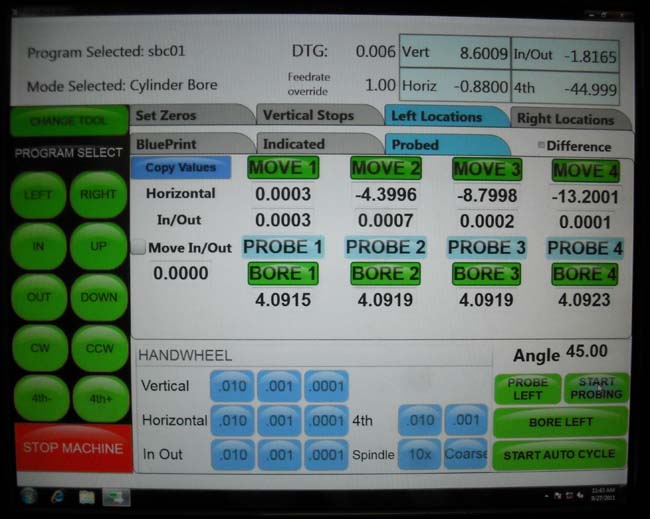

Automatic CNC Engine Block Blueprinting: CNC Probing.

CNC engine block blueprinting begins by making very accurate measurements of the existing cylinder bore, lifter bore and deck location compared to the blueprint locations so corrections can be made. Our CNC Engine Block blueprinting machine is equipped with the Renshaw probe which automatically locates and measures cylinder bores (diameters, locations and angles), deck heights, and lifter bores with the factory blueprint.

The Master machinist runs the automatic CNC probe routine comparing the entire block blueprint with the probed locations. The CNC Control displays the actual diameters and positions of the cylinder bores, lifter bores, deck heights and compares it to the factory specs. The operator then chooses to make any modifications necessary in order to maximize the maximum blueprinted specifications.

CNC Probing Engine Blocks R& L Engines Utiizes Renshaw

Probing is traditionally associated with contact probes used for dimensional measurement (metrology) on co-ordinate measuring machines (CMMs).

The first application of the original contact probe was in solving complex dimensional QA problems for the Rolls Royce Olympus engines used on Concorde.A probe is effectively an elaborate switch, designed to trigger on contact with a component surface, providing accurate, repeatable geometric data. Obtaining and interrogating this data throughout the manufacturing process can help to ensure components remain within conformance limits.

Accurate - deviating only slightly or within acceptable limits from a standard.

Precise (repeatable) - exact, as in performance, execution, or amount: accurate or correct.

CNC Lifter Bore Correction ,Sleeving and Blueprint

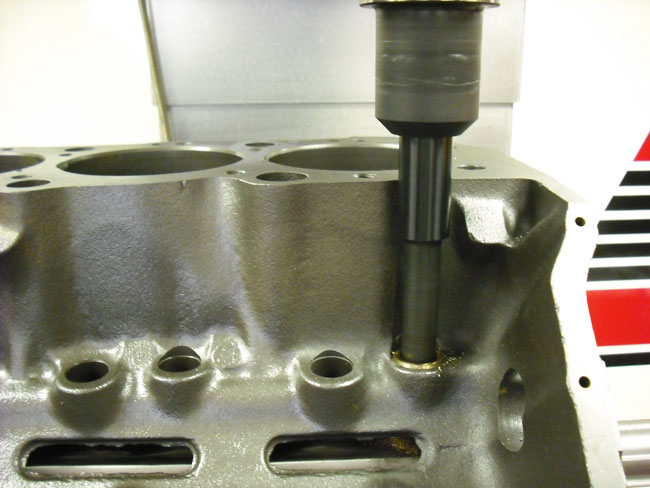

Machine lifter bores to the exact diameter, location and angle.True up the stock size and location or bore complete new diameter, location or angle. The Rottler F69A CNC Machine enables R & L Engines to re-machine the lifter bores and correct their position in an engine block front-to-rear and up-and-down, as well as to restore the correct lifter bore angle as referenced from the cam-crank centerline. Rottler F69A CNC Engine Block Blueprinting machine utilizes the Renshaw Probe with the lifter blueprinting program to positions the precise blueprinted lifter bore location and angles.

CNC Lifter Bore Correction ,Sleeving and Blueprint: Probing Routine

The CNC Probing Routing Verifies the lifter bores to the exact diameter, blueprint location and angle so corrections can be made to their position in an engine block front-to-rear and up-and-down, as well as to restore the correct lifter bore angle as referenced from the cam-crank centerline.

CNC Engine Block Line Boring

Our Rottler F69A CNC Engine Block Line Boring process utilizes the right angle drive line bore cutter head. This virtually eliminates bar sag found on traditional line boring machines. The end results is perfect alignment with round and straight main line bores.