(603)-742-8812

Established In 1981

Engine Rebuilding -Automotive Machine Shop

Vintage - Marine & Performance Engines

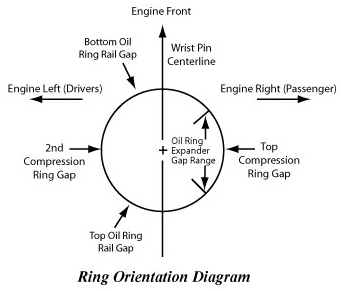

Everybody has a differing opinion when it comes to engine assembly & ring placement / end gap. You should always check and adjust the end gaps of the pistons rings when new rings are installed. Proper end gaps assures a good combustion seal thereby minimizing blow-by and allows proper clearance between the ends of the rings so they do not butt up against each other and cause the rings to scuff the cylinder walls.

The end gap is measured by placing the piston ring in the cylinder bore & squaring it to the bore. Squaring the rings in the bore will allow for an precise measurement of the end gaps.This can be accomplished either with a ring squaring tool or a piston. Insert a feeler gauge between the ends of the ring. If the gap is too narrow (less than the minimum recommended clearance), the ends of the rings can be filed to increase the gap. File carefully so that both ends of the ring remain parallel to each other. In other words, don't file at an angle. The ends of the ring must be square.

When measuring piston ring end gap, check the gap with the rings at the top and the bottom of the bore. If the bore has taper wear (bores typically wear most at the top), the end gap will be larger at the top and smaller at the bottom of the bore. Use the bottom position to set the end gap. If you use the top of a worn bore to set the end gap, the end gap will be too small when the piston reaches the bottom of the bore. The ends of the ring may hit each other causing the ring to bind and scuff. Cylinders that have more than .003 to .005 inches of taper wear should probably be bored or honed to oversize to restore proper piston and ring clearances. Refer to the engine manufacturer's specifications for the maximum allowable taper wear.

Piston Ring End Gap Recommendations

Most piston ring manufacturers recommend a minimum end gap of .004 inches times the bore diameter for the top piston compression ring. So for a 4 inch bore, the standard end gap would be .016 inches.

For the 2nd compression ring, the standard end gap recommendation for most stock engines is typically .005 in. x the bore diameter. So for a 4 inch bore, the minimum end gap on the 2nd ring would be .020 inches.

For a modified street performance engine that generates more horsepower and heat, the end gap should be opened up a bit to compensate for increased thermal expansion. The recommendation would be a minimum top compression piston ring end gap of.0045 to .005 inches times the bore diameter. For a 4 inch bore, the ring end gap on the top ring should be increased to .018 to .020 inches.

The 2nd compression ring on a modified street performance engine, the recommendation is typically open up the end gap to .0055 inches times the bore diameter. For a 4 inch bore, the 2nd ring would be gapped to .022 inches.

For a nitrous or blown racing engine, the top ring end gap should be opened up to as much as .006 or .007 inches times the bore diameter. Now we're looking at a 2nd ring end gap of .024 to .028 inches in an engine with 4 inch bores.

The 2nd ring on a nitrous or blown motor, the recommended ring end gap is even wider: .0063 to .0073 inches times the bore ( or 0.025 to 0.029 inches with a 4 inch bore).

The recommended ring end gap for oil rings regardless of the engine application is typically .015 inches.

Some racers believe that opening up the 2nd end gap even more (say an additional 10%) can improve overall ring sealing by allowing trapped gases to escape before they blow past the top ring and cause ring flutter at high rpm (say above 5000 to 6000 rpm).

NOTE: These recommendations are rules of thumb only. Always follow the end gap specifications recommended by the piston ring supplier or engine manufacturer.

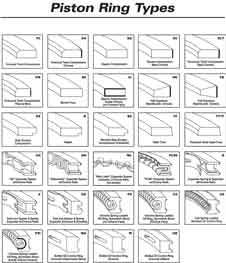

Manufacturers Piston Ring Instructions